Acoustic Foam Soundproofing: Enhancing Sound Quality and Reducing Noise

Acoustic foam soundproofing is a widely used method to control sound within various spaces, from recording studios and home theaters to offices and public spaces. This type of foam is typically made from materials such as polyurethane or melamine and is designed in various shapes like pyramids, wedges, and egg crates. These designs increase surface area, enhancing sound absorption by trapping sound waves and reducing reverberations. Acoustic foam, while effective at minimizing echo and controlling noise levels within a room, is often paired with additional soundproofing materials to prevent sound from leaving or entering the space.

This article delves into the properties, benefits, installation techniques, and limitations of acoustic foam soundproofing, providing a comprehensive guide for those looking to improve the acoustics in their environments.

Properties of Acoustic Foam

Acoustic foam soundproofing has distinctive properties that make it an effective choice for sound control:

- Material: Typically crafted from polyurethane or melamine foam, which are both known for their durability and sound-absorbing qualities.

- Density: Acoustic foam is available in various densities, directly influencing its sound absorption effectiveness.

- Shape and Surface Area: It comes in multiple shapes, such as pyramids, wedges, and egg crates, which maximize the foam’s surface area. Increased surface area allows the foam to absorb more sound waves, especially at higher frequencies.

The foam’s density and shape help in controlling sound reflections and echoes, creating a more acoustically controlled environment.

How Acoustic Foam Soundproofing Works

Acoustic foam works by reducing sound waves through absorption rather than reflection. Its unique properties and shapes allow it to absorb mid- to high-frequency sounds effectively, minimizing echo and reverberation. Here’s a breakdown of how it operates:

- Sound Absorption: Acoustic foam traps and absorbs sound waves, particularly high and mid-range frequencies, making it effective in rooms where these sounds dominate.

- Frequency Range: While excellent at controlling mid- to high-frequency sounds, low-frequency sounds often require thicker foam or additional soundproofing solutions like bass traps to achieve effective absorption.

- Surface Design: The specialized shapes of acoustic foam increase its surface area, allowing it to capture and absorb more sound energy.

Overall, acoustic foam soundproofing helps create an acoustically optimized space by dampening sound reflections and reducing noise distractions.

Applications of Acoustic Foam Soundproofing

Acoustic foam is versatile and beneficial across a variety of settings where sound control is essential:

- Recording Studios: Acoustic foam soundproofing is a staple in recording studios, providing a controlled environment by reducing echo and background noise.

- Home Theaters: This foam improves sound clarity, creating a theater-like experience by minimizing sound reflections.

- Offices: Acoustic foam panels in office spaces reduce noise distractions, enhancing speech clarity and productivity.

- Public Spaces: In places like restaurants, auditoriums, and gyms, acoustic foam helps control noise levels, making these areas more comfortable for patrons.

Installation Tips for Acoustic Foam Soundproofing

Effective installation of acoustic foam is critical to maximizing its benefits. Here are some essential tips to consider:

- Coverage: For noticeable improvement in sound quality, cover at least 20-30% of the wall surface with acoustic foam. More coverage generally leads to greater sound absorption.

- Placement: Position foam panels at the first reflection points, such as corners and wall junctions, where sound waves tend to concentrate.

- Adhesion Methods: Spray adhesives, double-sided tape, or mounting brackets can be used for secure installation. Ensure the wall surface is clean to promote strong adhesion.

Following these installation tips will help achieve the best possible acoustic environment within your space.

Benefits of Acoustic Foam Soundproofing

Acoustic foam soundproofing offers several benefits that make it a preferred choice for sound control in numerous environments:

- Enhanced Sound Quality: By absorbing sound waves, acoustic foam improves sound clarity, making it essential for settings where audio quality is important, such as recording studios and home theaters.

- Reduced Echo and Reverberation: The foam effectively minimizes echoes and reduces reverberation, making spaces more comfortable and acoustically pleasant.

- Improved Speech Clarity: In office environments, acoustic foam helps reduce ambient noise, allowing for clearer communication.

- Versatility and Customizability: Acoustic foam comes in various shapes, densities, and colors, allowing customization to meet the acoustic and aesthetic needs of different spaces.

Effectiveness and Limitations of Acoustic Foam Soundproofing

While acoustic foam soundproofing is effective in enhancing sound quality within a room, it is essential to understand its limitations.

- Echo Control, Not Full Soundproofing: Acoustic foam soundproofing reduces echoes and improves room acoustics but does not entirely block sound from entering or exiting the space. True soundproofing typically requires additional materials such as mass-loaded vinyl, drywall, or resilient channels.

- Enhanced Effect with Other Materials: For rooms with a high level of sound insulation requirements, it is best to pair acoustic foam with other soundproofing materials.

Despite these limitations, acoustic foam remains a reliable and cost-effective solution for echo and reverberation control, especially when used in combination with other soundproofing materials.

Maintenance of Acoustic Foam Soundproofing

To ensure the longevity of acoustic foam panels, regular maintenance is advised:

- Cleaning: Dust the foam regularly using a vacuum cleaner or a soft brush. Avoid using water or harsh chemicals, as these can degrade the material over time.

- Durability: Acoustic foam is generally durable; however, it may deteriorate with prolonged exposure to sunlight or moisture.

Proper maintenance can extend the life of acoustic foam and keep it effective in sound absorption.

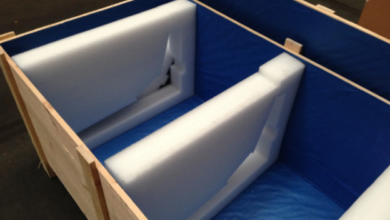

About Acoustafoam

Founded in 1979, Acoustafoam Limited specializes in the manufacture of foam, rubber, and plastic components for soundproofing. Based in Telford, Shropshire, the company has over four decades of experience providing acoustic solutions across various industries, including automotive, marine, construction, and public transport. Acoustafoam offers high-quality acoustic products such as custom cut kits and molded foam, designed to meet the specific needs of each client.

Acoustafoam is ISO 9001:2015 certified, ensuring consistent product quality and excellent customer service. The company operates with a strong commitment to innovation, utilizing state-of-the-art equipment and techniques to deliver top-notch soundproofing solutions. The dedicated in-house technical team at Acoustafoam provides professional support, making them a trusted choice for acoustic foam soundproofing products.

Vision and Mission of Acoustafoam

Acoustafoam’s mission is to incorporate innovation and integrity into its products and partnerships, investing in technology and training to stay at the forefront of the acoustics industry. The company’s vision is to become a global leader and preferred supplier, recognized for quality and exceptional service in acoustic foam soundproofing and noise control.

Acoustafoam’s Diverse Industry Applications

Acoustafoam serves a range of industries with custom acoustic solutions:

- Automotive: Supplies components to reduce noise in vehicles, enhancing comfort and sound quality.

- HVAC Systems: Provides soundproofing solutions for quieter heating, ventilation, and air conditioning systems.

- Marine and Boats: Specializes in producing materials for soundproofing in marine applications, where noise reduction is critical.

- Medical: Offers medical-grade foam products, designed to meet high specifications for soundproofing and comfort.

- Military Vehicles: Supplies high-specification acoustic products for military applications, ensuring both safety and noise reduction.

Future Goals and Technological Advancements

Acoustafoam aims to continually develop its management system by using modern visual aids linked to control stations at each production line. This system enables precise forecasting, improving production efficiency and customer service. Acoustafoam is dedicated to maintaining and advancing quality and technology, striving to remain competitive and responsive to industry demands.

Read Also: Affordable LED Grow Lights: Enhancing Indoor Gardening Experience

Conclusion

Acoustic foam soundproofing is a valuable tool for managing sound within spaces where clarity and echo control are essential. While acoustic foam is highly effective at absorbing mid- to high-frequency sounds and reducing reverberation, it should be combined with other materials for complete soundproofing. Acoustafoam Limited, with its commitment to quality and innovation, offers a wide range of custom acoustic solutions that cater to various industries.

Whether enhancing the acoustics of a recording studio or reducing noise levels in public spaces, Acoustafoam’s products are a reliable choice. With their expertise and customer-centric approach, Acoustafoam continues to lead the way in acoustic foam soundproofing, helping businesses and individuals create acoustically optimized environments.